Electronics Production

Milling an example (pre-designed) FTDI adapter

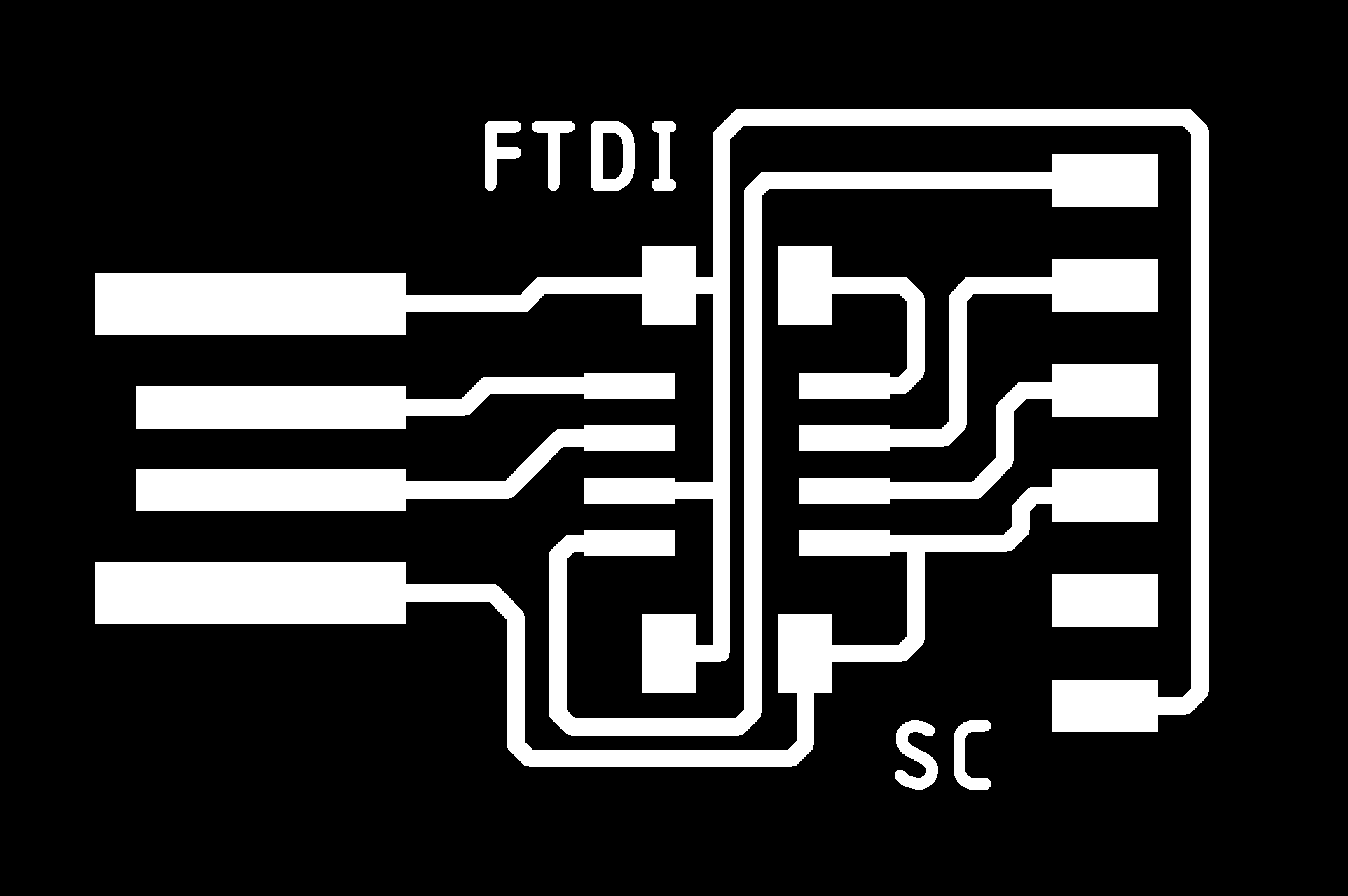

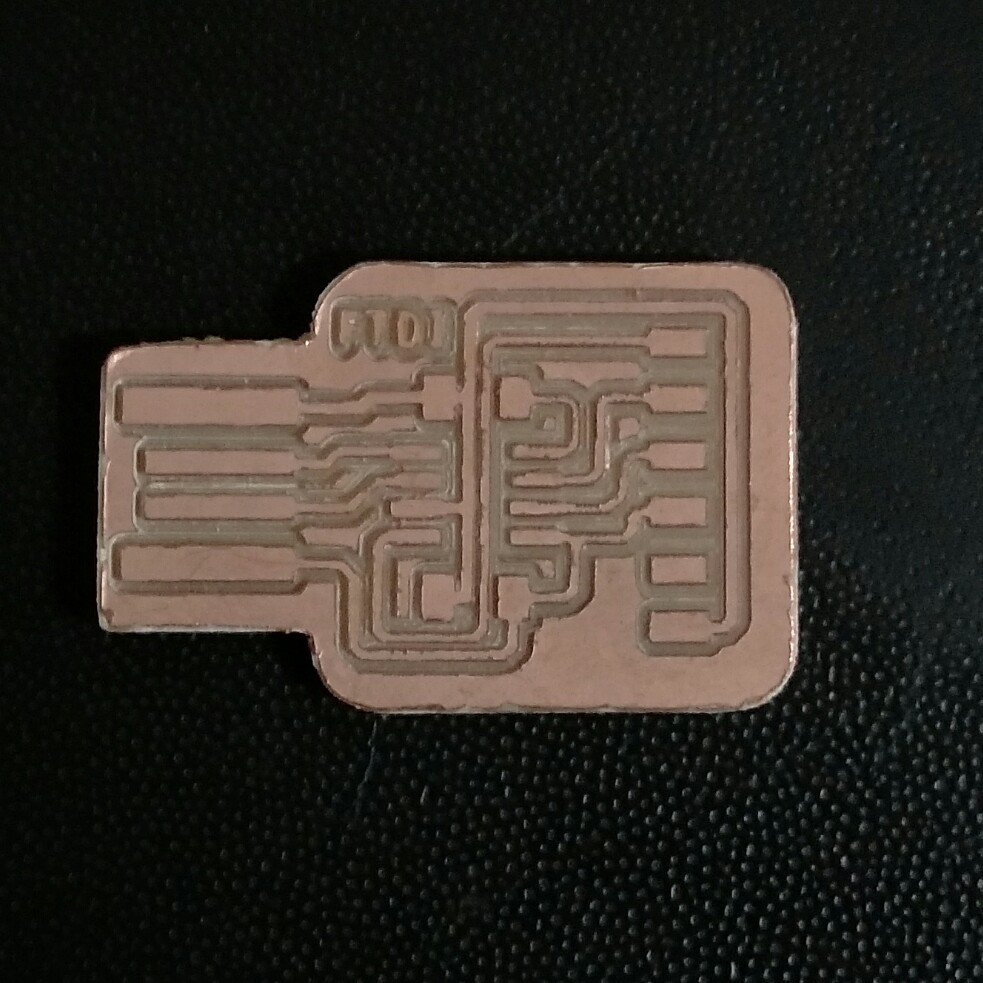

These are the PNG files provided.

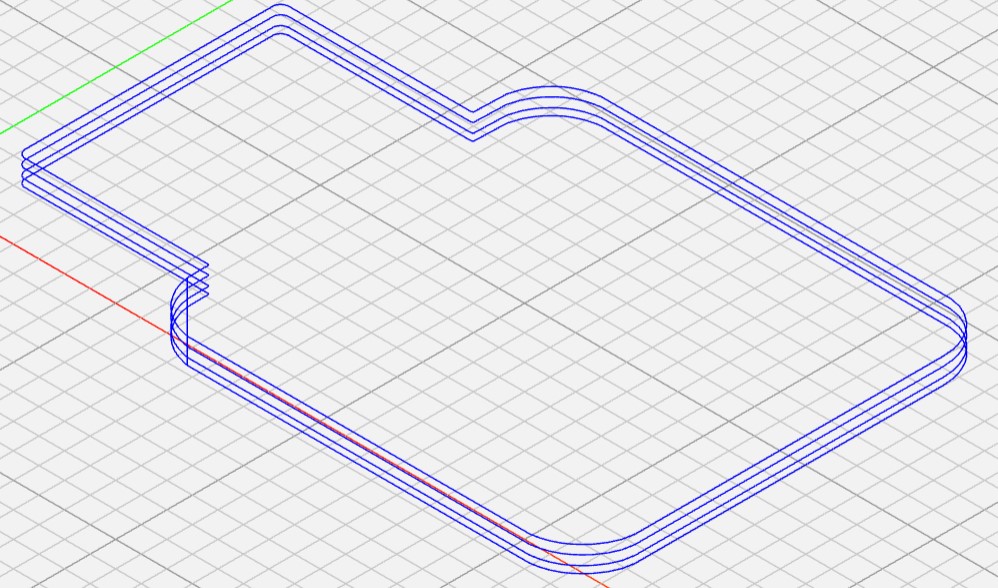

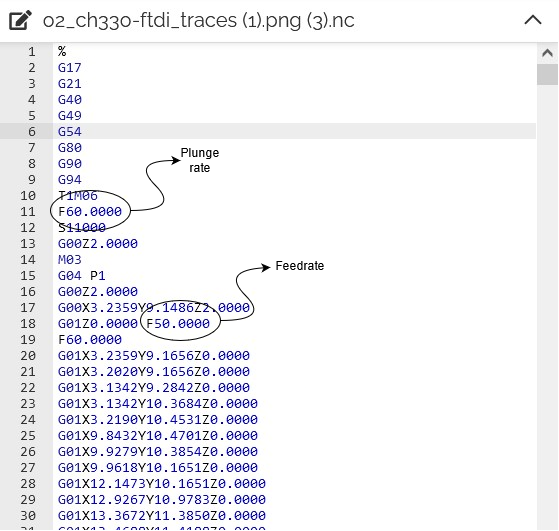

In order to prepare these files for milling, they need to be converted into Gcode.

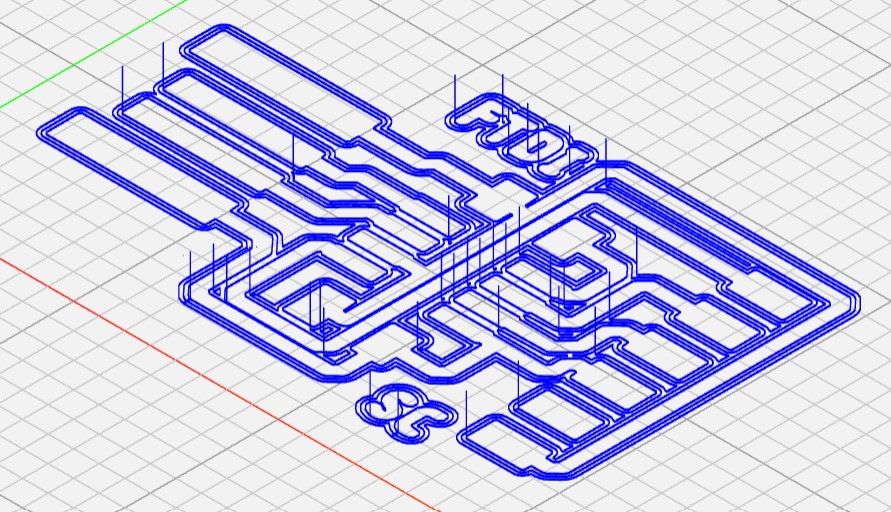

Using the mods tool, i was able to convert the black and white png file into "nc" files, that can be read by the milling machine.

Important checks before milling:

Milling of PCB:

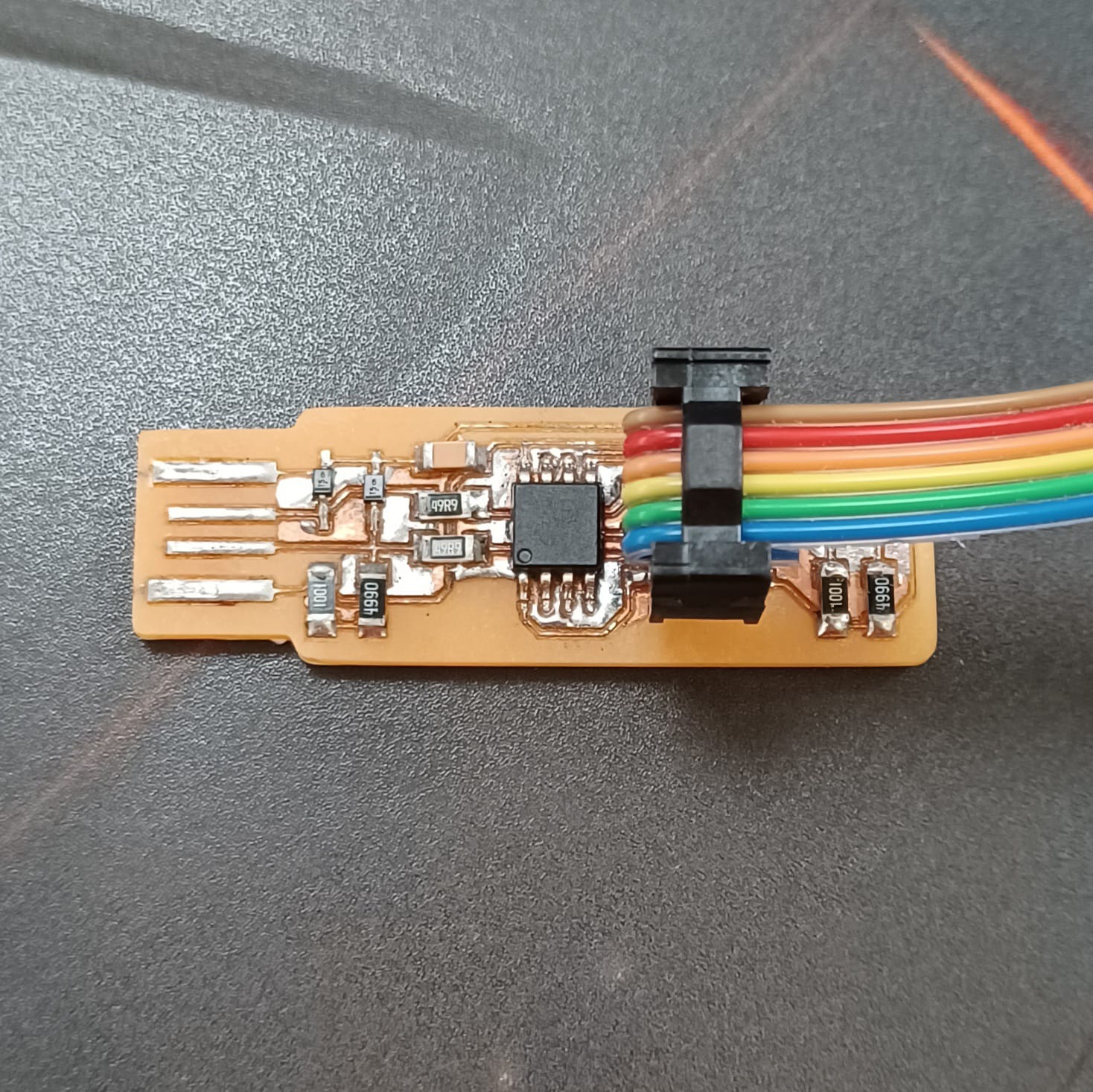

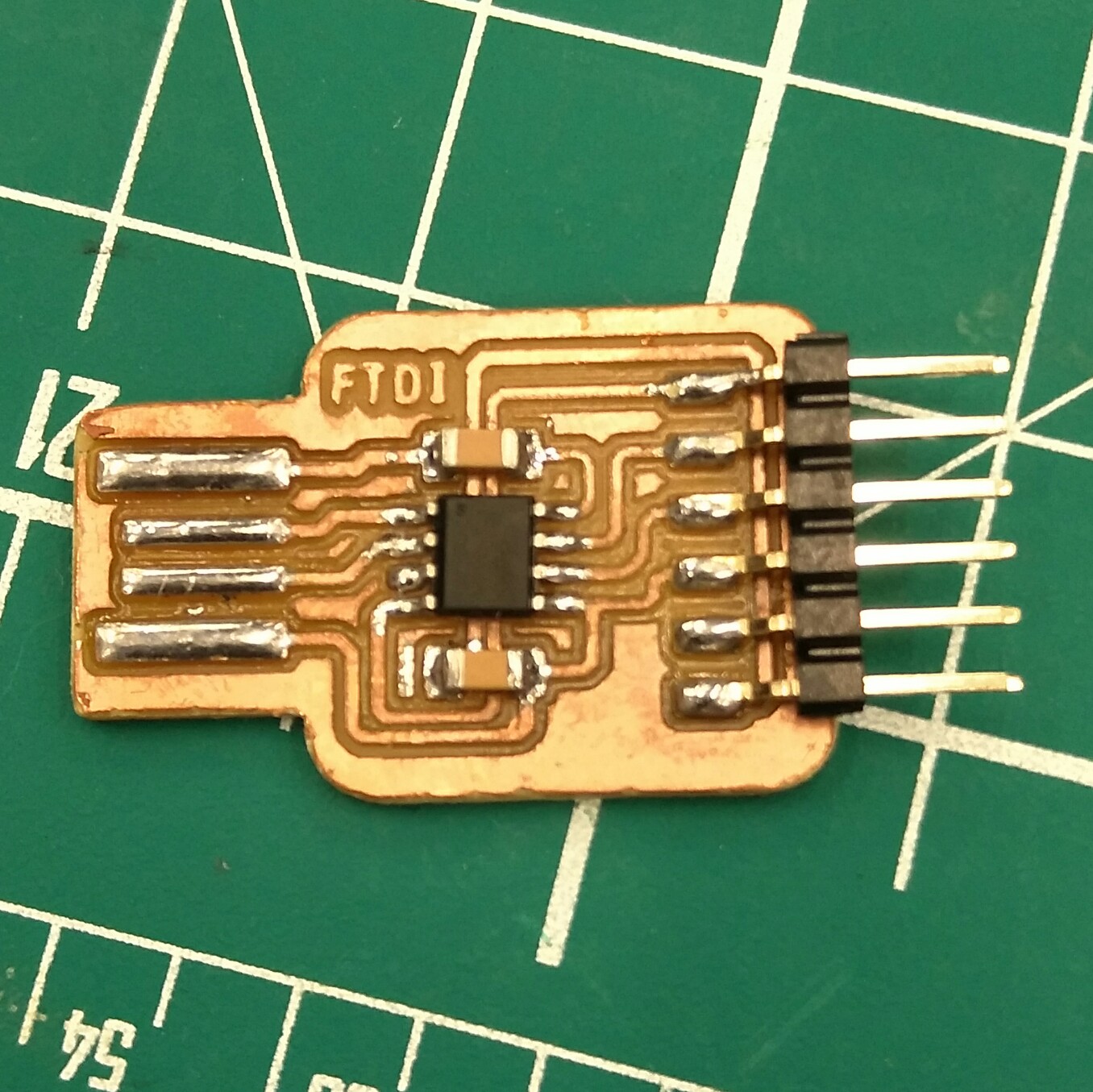

This is the milled PCB (i had to end the milling early due to time constraints, hence the absense of the SC text):

After soldering:

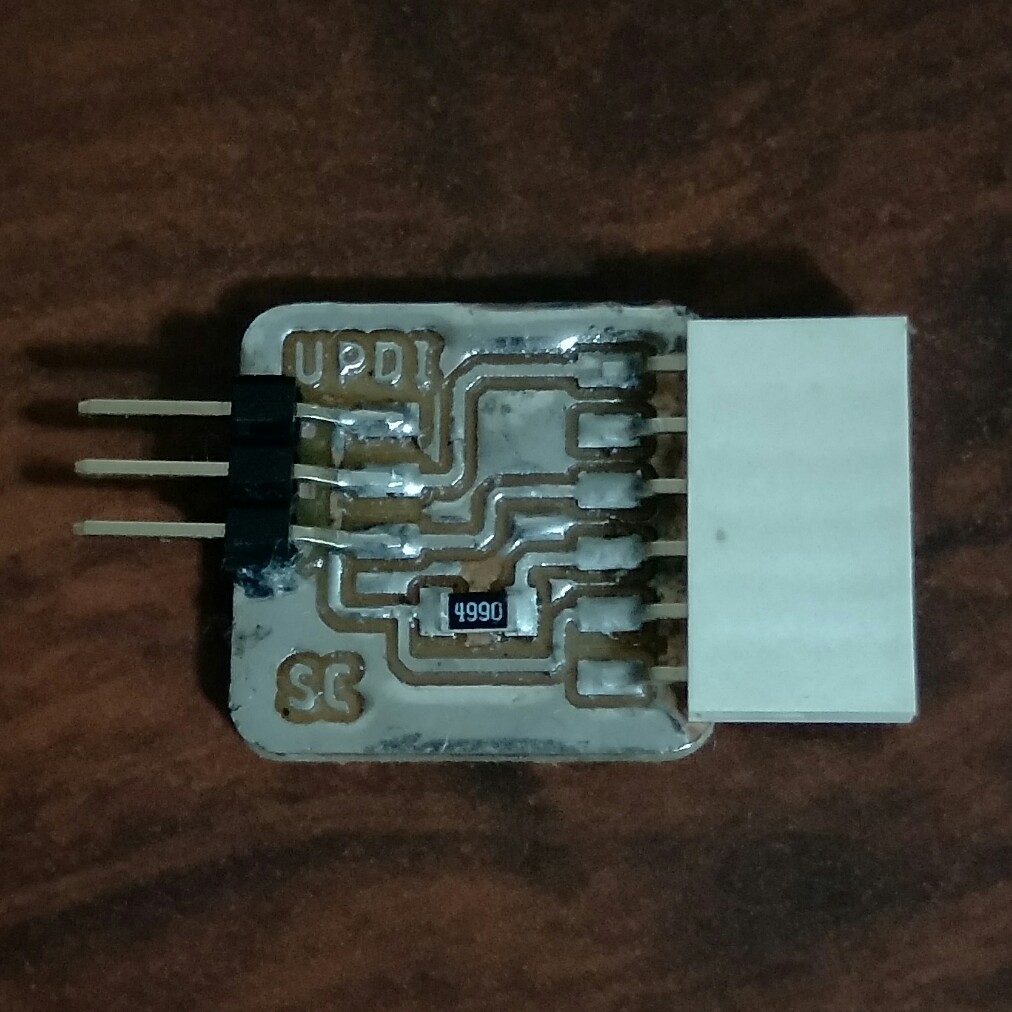

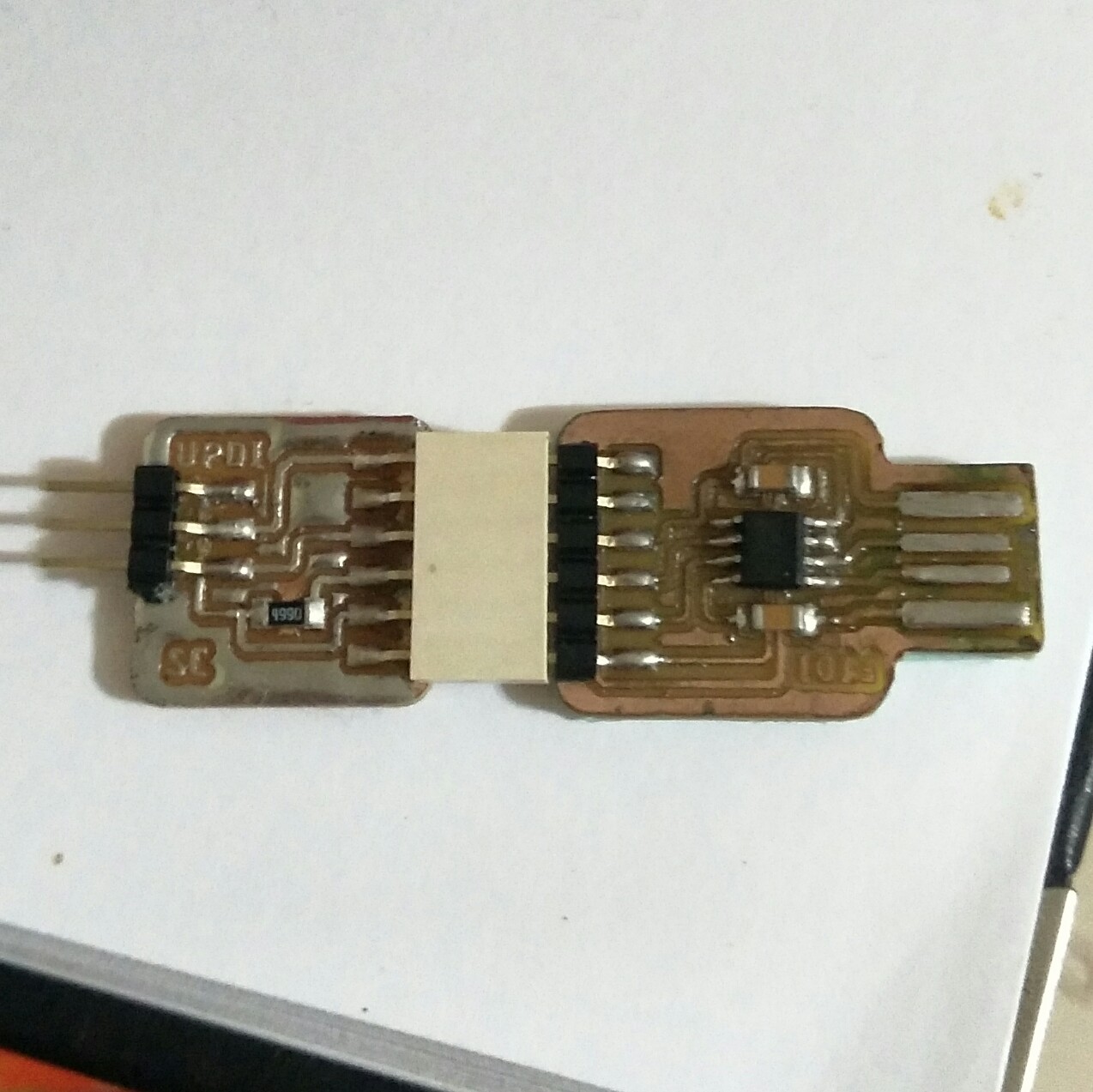

Another premilled UPDI board:

Due to time constraints, i brought the board home and used 60/40 solder at 320, to put this board together.

This is the finished product.

Using the same process, i made (converted png file, milled board and soldered) the USB ISP programmer. Due to incorrect settings and inexperience, the thin traces kept getting pushed off, and it took me 5 tries to make a working board.